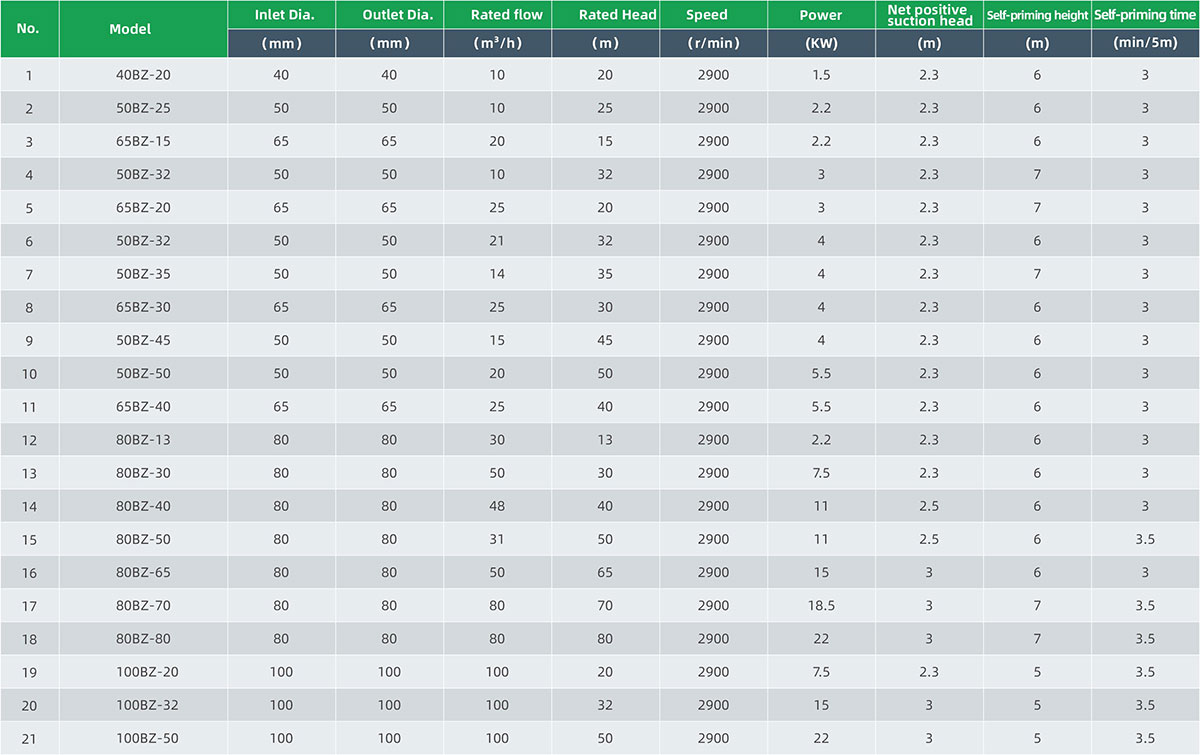

The BZ series pump is a horizontal self priming pump. This type of pump is compared to other types of self priming centrifugal pumps because the pump itself does not have a check valve and has a simple structure; Reliable work; Long trouble-free working time, easy maintenance and use, small size, light weight, high efficiency, and special consideration in design compared to pumps of the same caliber, resulting in large displacement and high performance.

The BZ type self priming pump is more effective as an emergency pump in industrial and agricultural production, emergency rescue, such as flood drainage and fire fighting. The BZ pump is widely used for urban water supply in industrial sectors such as petroleum, chemical, metallurgical, mechanical, chemical fiber, food, energy, transportation, etc. It can also be used for agricultural drainage and sprinkler irrigation. For conveying clean water or viscosity less than 5° E. Other liquids with physical and chemical properties similar to water at temperatures below 80 ℃.

The characteristic of this self priming centrifugal pump is its simple and reliable structure, and its durability. Under normal pump conditions, it is generally not necessary to disassemble and maintain the pump frequently. When a malfunction is found, it can be eliminated at any time< br/>

When maintaining the pump, attention should be paid to several main parts:

a. Rolling bearing: When the pump is running and the bearing is worn to a certain extent, it must be replaced< br/>

b. Front sealing ring and rear sealing ring: When the sealing ring is worn to a certain extent, it must be replaced< br/>

c. Mechanical seal: Mechanical seals should not be opened for inspection in general, provided they do not leak liquid. If severe leakage occurs at the leakage port at the lower end of the bearing body, the mechanical seal should be disassembled and inspected. When installing and disassembling mechanical seals, it is necessary to handle them with care, pay attention to the cleanliness of the mating surface, protect the mirror surface of the static and dynamic rings, and strictly prohibit knocking and collision. The main cause of leakage caused by mechanical sealing is the roughening of the friction mirror surface. The repair method can be to grind the end face of the friction pair to restore the mirror surface. Another reason for leakage in mechanical seals is" O"&# 39; Improper installation or deformation and aging of the O-ring (or buffer pad). At this point, it is necessary to adjust or replace the" O&# 39; Reassemble the O-ring seal< br/>

2. Pump disassembly sequence:

a. Remove the motor or remove the coupling< br/>

b. Remove the bearing body assembly, check the radial clearance between the impeller and the front ring, and check if the impeller nut is loose< br/>

c. Remove the impeller nut, pull out the impeller, and check the radial clearance between the impeller and the rear sealing ring< br/>

d. Loosen the fastening screws of the mechanical seal, pull out the dynamic ring part of the mechanical seal, check the fit of the dynamic and static ring end faces, and check" O” The sealing condition of the O-ring (or buffer pad)< br/>

e. Unscrew the fastening nut of the coupling and pull out the coupling< br/>

f. Remove the bearing end cover and remove the pump shaft and bearings< br/>

g. Assemble in reverse order during installation.

LULIN Pump looks forward to your call,Our national service hotline:+86-400-8820-878

CONTACT US